How to connect roller chain?

- Teilen

- Ausgabezeit

- 2024/4/16

Zusammenfassung

To connect roller chain, align the ends and insert a connecting link pin. Ensure the pin's head faces toward the direction of chain travel. Press the pin into the chain, leaving a small gap between the link plate and roller. Insert the retaining clip, ensuring it's fully seated in the grooves of the link plates for secure attachment.

How To Connect Roller Chains?

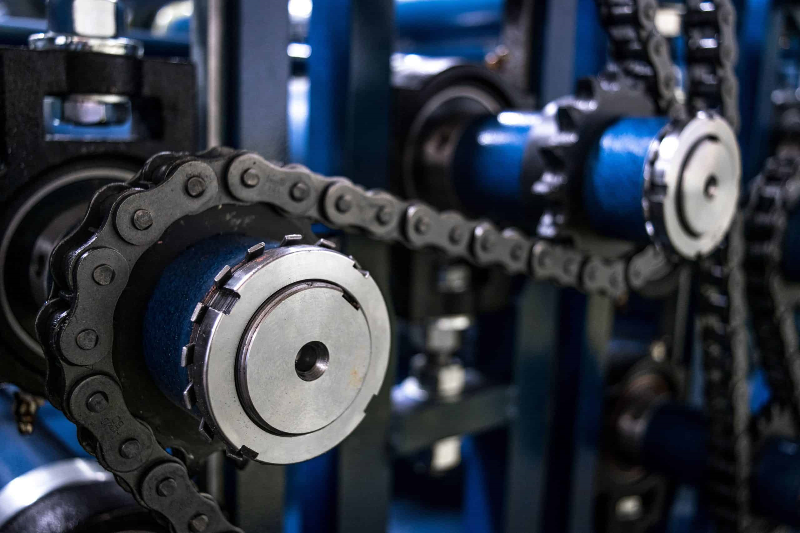

Proper installation of roller chains is critical to their performance and longevity. Don't worry, after these three steps, you can easily install the roller chain on the chain sprocket.

Step 1

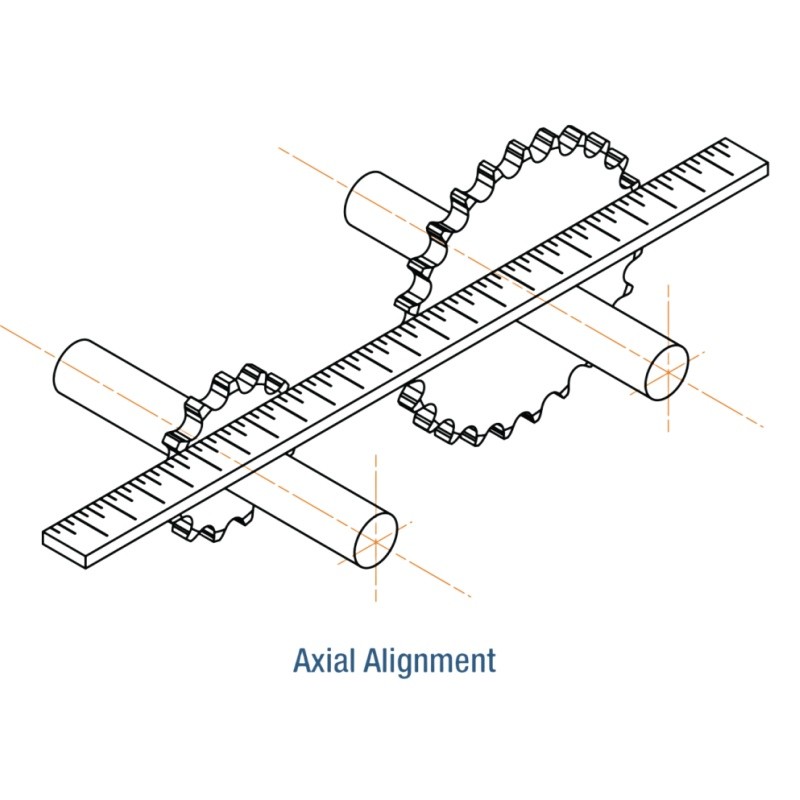

The first step is to make sure that the sprockets are aligned correctly. Misaligned sprockets can cause premature wear and reduced efficiency, so it is critical to check the alignment with a straightedge or laser tool. The sprockets should be parallel and the chain should run directly from the drive to the drive sprocket.

Step 2

Next, the roller chain should be threaded onto the chain sprockets, making sure any master links are installed for easy identification and access. The deflection or sag of the chain must be set correctly. Too little deflection (over tightening) can cause excessive wear on the chain and sprocket, while too much deflection (under tightening) can cause the roller chain to jump off the sprocket. A good rule of thumb is that the chain should deflect about 1/120th of the distance between the centers of the sprockets at moderate pressure.

Half links, also known as offset links, are used to increase or decrease the length of the chain by one pitch for better fit and tension adjustment. They are useful when the length of the chain does not exactly match the distance between the sprockets, ensuring smoother operation.

Step 3

Finally, after installation, make sure the chain is adequately lubricated to reduce friction and wear. Remember that regular inspection and maintenance can extend the life of the roller chain and ensure efficient power transmission of the machine.

Installation of roller chains requires a special set of tools to ensure an efficient and safe installation process. These include a chain breaker tool to separate and break links, a chain puller to help tension the chain, a straightedge or laser alignment tool to verify sprocket alignment, and the proper lubricant to reduce friction and wear.

In addition, master link pliers may be required to handle the master links. The use of these tools is critical as they help prevent improper installation and ensure the life and optimum performance of the roller chain. Missteps during installation can lead to premature wear of the roller chain, reduced efficiency, and potential failure.

For over fourteen years, CTS® has dedicated itself to crafting top-quality roller chain and drive components. Our specialization extends to providing superior power transmission parts and custom-designed products. If you're seeking a reliable Roller Chain solution, look no further. With a full range of ANSI Roller Chains and Metric Roller Chains at your disposal, our experienced team is ready to assist you in finding the perfect fit for your needs. Trust CTS® to deliver excellence and efficiency every step of the way.

To browse our excellent products, please visit our ChinaTransmissions.com or contact us via email at info@chinatransmissions.com or call 0086-18667944319(WhatsApp/WeChat).

If you have any questions, please feel free to contact us, CTS® professional technicians will be happy to help you!