How to Extend the Lifespan of Roller Chains

- Teilen

- Ausgabezeit

- 2024/9/25

Zusammenfassung

In this blog, we will explore practical tips and best practices for maintaining and caring for industrial chains, ultimately extending their lifespan.

Roller chains are crucial components in various industrial applications, powering everything from conveyors to machinery in factories. Their durability and efficiency are vital for smooth operations, but they can experience wear and tear over time.

In this blog, we will explore practical tips and best practices for maintaining and caring for industrial chains, ultimately extending their lifespan.

The Common Types of Roller Chain Wear

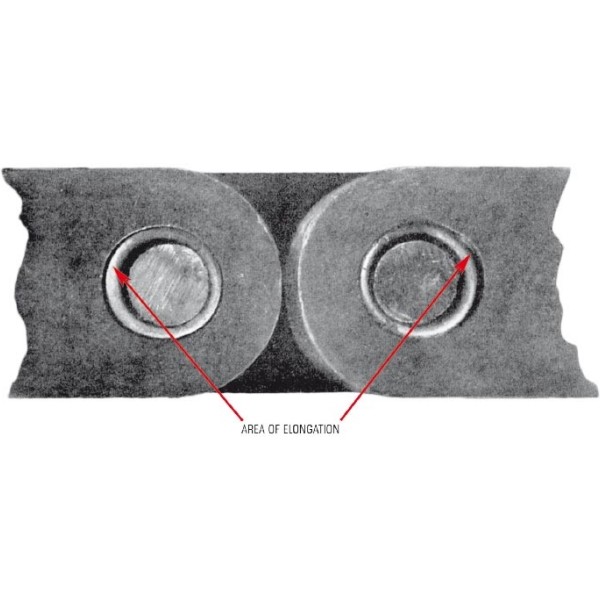

Roller Chain Elongation

As chains operate, they naturally elongate due to wear on the pins and bushings. Over time, this can lead to poor performance and increased tension in the drive system.

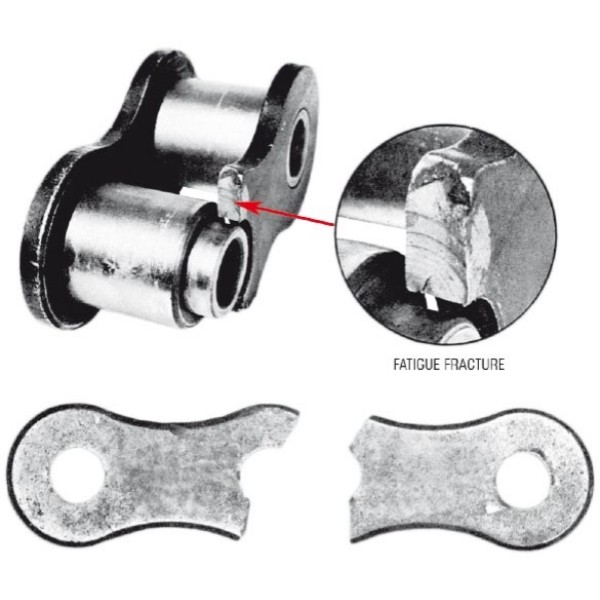

Roller Chain Surface Fatigue

Frequent load cycles cause surface fatigue, leading to pitting or flaking on the chain’s surface. This compromises the integrity of the chain.

Roller Chain Corrosion

Environmental factors like humidity and exposure to chemicals can lead to rust and corrosion, weakening the chain.

Comprehensive Roller Chain Maintenance Program

Roller Chain Lubrication

Types of Lubricants

• Oils: Mineral or synthetic oils provide excellent lubrication but require more frequent application.

• Greases: Greases are thicker and provide a longer-lasting film, suitable for high-load applications.

Application Techniques

• Drip Feed: Ideal for continuous lubrication, ensuring a steady supply.

• Manual Application: Regularly check and manually lubricate chains in less accessible areas.

• Automatic Lubrication Systems: Install systems that automatically distribute lubricant at set intervals.

Frequency of Lubrication

• High-load Conditions: Lubricate every 8-10 hours of operation.

• Normal Conditions: A weekly lubrication schedule is often sufficient.

Roller Chain Cleaning

Regular cleaning prevents debris build-up and extends the chain’s lifespan.

Cleaning Steps

1) Remove the Chain: For thorough cleaning, detach the chain from the equipment.

2) Use a Brush: Employ a stiff-bristled brush to scrub off dirt and debris.

3) Solvent Cleaning: Soak the chain in a solvent (like mineral spirits) to dissolve old lubricants and contaminants.

4) Drying: Allow the chain to dry completely before re-lubricating and reinstalling.

Frequency of Roller Chain Cleaning

✔ Dusty Environments: Clean weekly.

✔ Normal Operating Conditions: Monthly cleaning is generally sufficient.

Ensuring Proper Alignment and Tension

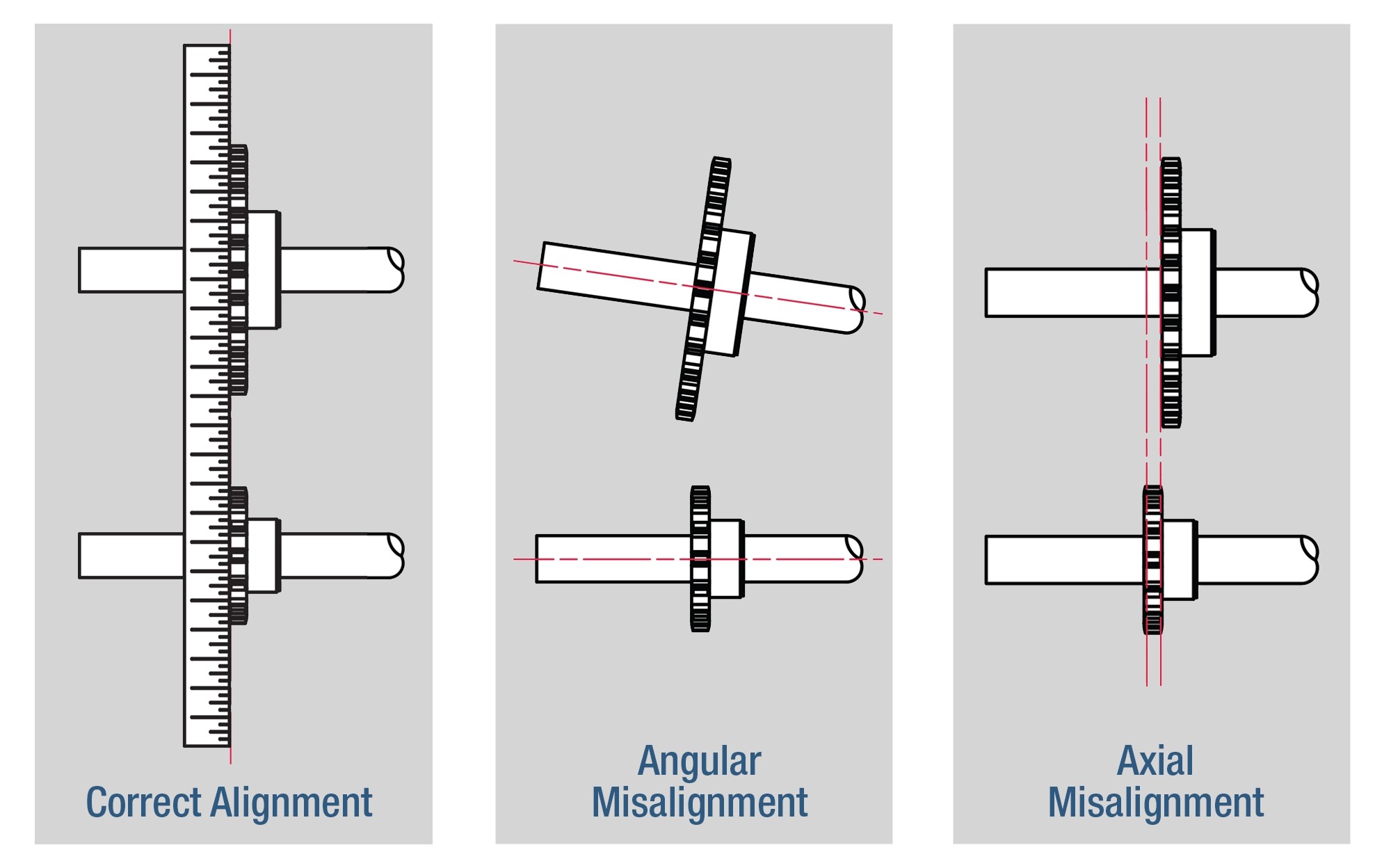

Alignment Techniques

Proper alignment is crucial for minimizing wear and maximizing chain efficiency.

Checking Alignment

Use a laser alignment tool to ensure sprockets are properly aligned.

Inspect visually for any signs of wear on the sprocket teeth, indicating misalignment.

Adjusting Alignment

Loosen the mounting bolts of the drive and idler sprockets.

Adjust the position of the sprockets until they align correctly.

Retighten bolts after achieving proper alignment.

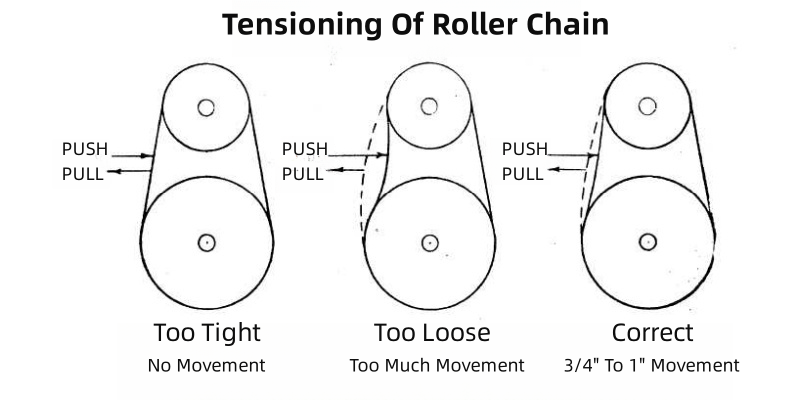

Optimal Tensioning

Maintaining the correct tension is critical for the performance and longevity of roller chains.

Tensioning Guidelines

Ideal Tension: The chain should have a slight sag when installed, usually about 1-2% of the total span length.

Use a tension gauge to measure and adjust accordingly.

Adjustment Techniques

Adjust tension using the tensioning mechanism provided in the equipment or add/subtract links as needed.

Choosing Qualitify Roller Chain

Using high-quality roller chains can significantly reduce maintenance costs and enhance performance.

CTS-ChinaTransmissionS is a professional manufacturer, we supply high-quality roller chains, and our roller chains are made from high-grade materials that resist wear and fatigue.

Managing Operating Conditions

External conditions can significantly affect chain lifespan.

✔ Use Protective Covers: Shield chains from dust, moisture, and chemicals.

✔ Select Appropriate Materials: Use chains made from materials that resist environmental degradation.

Load limits are critical for maintaining chain integrity.

✔ Dynamic Loads: Assess the actual load experienced during operation.

✔ Static Loads: Ensure loads do not exceed specified limits when the system rests.

As a professional roller chain manufacturer, we supply high-quality roller chains. Whether you need standard or customized roller chains, Contact us, our technicians will be happy to help you!